What is Microfibre Fabric: Properties, How its Made and Where

Recently, the popularity of microfibre has endured a significant hit due to the ongoing controversy surrounding microfibre pollution. Despite the somewhat misleading nomenclature, microfibre fabric is not the greatest contributor to microfibre pollution, and common fabrics such as polyester and rayon actually contribute to this ecological disaster far more than microfibre fabric. Partially due to its name and also due to the fact that microfibre does, indeed, contribute to microfibre pollution, consumer sentiment toward this useful and inexpensive fabric has worsened.

Microfiber vs. Cotton Sheets: What’s the Difference?

Soft, silky, sumptuous sheets—they’re the reason you never want to leave your bed in the morning and the soft haven that beckons you to sleep each night. So how do you decide between microfiber vs cotton when the material of your bed sheets can make or break your slumber?

The main difference between the two materials is their origins. Microfiber is created from synthetic textiles, while cotton is developed from organic materials. While both materials generally are known for their soft textures and durability, when deciding between microfiber vs cotton bed sheets, the nuances between materials create a greater basis for comparison.

Keep reading to unearth the differences between microfiber vs cotton sheets so that you can choose wisely and sleep soundly.

With a variety of bed sheets to choose from, Casper has something for every preference. Find bed sheets that will suit your slumber.

What Is the Difference Between Microfiber and Cotton?

The difference between microfiber and cotton comes down to substance.

- Cotton is a fiber sourced from the cotton plant

- Microfiber is an inorganically engineered blend of synthetic materials such as polyester or wood pulp.

Both materials are utilized for a variety of purposes. From clothing manufacture to —most notably— the production of bed sheets, these two materials jointly reign the textile industry.

What Is Microfiber?

Microfiber is a man-made, synthetic material formed through a chemical process. It is composed of materials such as polyester, nylon polymers, or wood pulp. Unlike their natural-fiber counterparts, materials made with microfiber are less prone to shrinking and wrinkling while still maintaining a soft and durable feel.

The production of microfiber began as a cost-effective and easily-massed-produced alternative to natural fibers. Though microfiber was conceived as a cheaper alternative to natural fibers, the textile has evolved into a greatly desired material due to its soft, sleek feel, water and stain resistance properties, and affordability.

Nowadays, there are a variety of microfiber options in the textile industry that range in quality and production techniques. The differences between microfiber materials include the following:

- GSMrating – Grams per square meter—or GSM—refers to the weight of the microfiber fabric. The higher the GSM rating, the better the material. A GSM rating over 100 indicates a higher thread density—resulting in a stronger, more durable microfiber—while a GSM rating below 90 is considered low-quality.

- Brushed vs unbrushed – The process of brushing microfiber fabric involves gently brushing each microfiber to create an ultra-soft, velvety texture. The quality of microfiber can be determined by whether the fabric has been brushed, double-brushed (when the same process is applied to both sides of the microfiber), or not.

Though derived from humble origins, microfiber has deservedly become a fair competitor against natural fibers sold within the textile industry. Its soft sateen feel, moisture-wicking capabilities, and—above all else—stellar affordability ensure that microfiber will always be a material that consumers love.

What Is Cotton?

Cotton is a natural fiber procured from the cotton plant. Cotton’s use dates back to the fifth millennium B.C. Although it progressively garnered attention throughout history as a widely-used textile, cotton’s true claim to fame came with the rise of the industrial revolution. With the rise of innovative production techniques, cotton’s soft, long, and strong fibers became a star staple in the world of textiles.

As a staple fiber—a material composed of various, differing lengths—cotton is produced by twisting its fibers together in order to form a long, continuous yarn. Known for its softness, durability, breathability, and its capacity to both absorb liquid and hold dye well, cotton has staked its claim as a viable, versatile fabric in the sphere of textile materials.

As the production of cotton has developed throughout time, so has humankind’s innovation of fiber and plant. Today, there are differing genomes of cotton grown and produced throughout the world—each with its own distinct qualities and characteristics—available for consumers to enjoy. The four most popular genomes include:

- Pima cotton – Pima cotton has long fibers that contribute to both its softness and its durability. Because of its resistance to fraying, tearing, pilling, wrinkling, and fading, pure pima cotton is often used for sheets.

- Egyptian cotton – Born of the same genus of pima cotton, this specific fiber is harvested from cotton plants that grow—surprisingly— both in Egypt and in South America. As an extra-long staple cotton, Egyptian cotton is known for its softness and durability. These features make an Egyptian cotton sheet a sound investment.

- Upland cotton – Characterized by its short fibers, upland cotton is the most widely-produced cotton in the world. Upland cotton tends to be a more affordable cotton option.

- Organic cotton – Organic cotton refers to any genome of cotton that is grown without chemicals, from plants that have not been genetically engineered. Because of its eco-friendly nature, fabrics made with 100% organic cotton, such as Casper’s luxuriously soft sateen sheets or blissfully breathable percale sheets, remain a coveted option for fabric and textile purchases. All cotton sheets from Casper are only made with this type of cotton, but come in various weaves depending on your preference.

Following the harvest of the cotton plant, cotton fibers are woven into materials using techniques specific to their desired softness or durability. When searching for cotton products, keep an eye out for these distinctive terms:

- Sateen – Sateen weave refers to a cotton fabric made with a satin weave. This weave produces a material with a soft, lustrous feel.

- Percale – Percale is a closely woven, plain-weave fabric. Its softness, crispness, and strong durability make it the elected fabric choice for bedding.

In addition to the origin and weave of its cotton fiber, the thread count of cotton determines the textile’s quality as well. Thread count is a measurement of the fineness or coarseness of fabric. When looking for the best cotton sheets, look for a thread count between 200 and 400; any thread count lower than 180 tends to have a rough texture, while a thread count of about 400 is most likely an inflated figure that does not equate to softness.

Comparing the Two

Now that you know what microfiber and cotton are, let’s move on to the question that you really want answered—which is right for you? When deciding on how to buy sheets that are right for you, it’s best to break down how each fabric measures up in a few key categories:

- Cost – Depending on source and quality, microfiber and cotton can run the gamut between affordable and luxury pricing. However, the involved process of cotton production, plus its esteemed reputation, generally make cotton more expensive. Microfiber, on the other hand, is a lot cheaper to produce. This typically makes microfiber a little more affordable.

- Durability – Both microfiber and cotton are extremely durable materials that, with proper care, will stand the test of time. However, cotton tends to be more reliable if you want something that upkeeps a cozy feel.

- Feel – Cotton is acclaimed for its breathability and ultra-soft feel. Its temperature-regulating abilities make it perfect for hot and cold sleepers alike, and its lightweight character gives it its signature “barely there” feel. Microfiber sheets offer a sleek, satiny feel reminiscent of silk. Its moisture-wicking abilities and thin profile ensure that it provides a soft, silky element to your bedding.

- Maintenance – While cotton is made to last, cotton bedding is prone to wrinkling and shrinking with improper care. The textile also absorbs stains easily. Therefore, cotton requires frequent, careful washing in order to maintain its quality. Though microfiber bedding does wrinkle, its naturally stain-resistant qualities and ability to withstand frequent washing make it slightly less maintenance than its cotton counterpart.

- Allergen-friendliness – When determining what the best sheets for allergies are, cotton bedding happens to be hypoallergenic. Why? Cotton fiber’s cool, breathable nature proves a difficult environment for bacteria and mold to thrive in. Microfiber, however, is not hypoallergenic, and may not be the best fit for sleepers with allergies or sensitivities.

- Environmental Impact – Natural fibers, such as cotton, have a smaller environmental impact than synthetic fiber because they do not require as many chemicals for production. If eco-friendliness is in question in the decision of microfiber vs cotton, cotton sheets definitely leave a lighter impact on the environment.

Which is Better, Microfiber or Cotton?

In the debate between microfiber vs cotton sheets, the answer for which is better is highly dependent on individual preference. Quality cotton sheets bolster cotton’s famed breathability, versatility, and sigh-worthy softness. Their eco-friendliness—combined with cotton’s temperature-regulating and hypoallergenic qualities—make high quality cotton sheets a sound investment for any sleeper.

Microfiber, though a synthetic material, does not pale in comparison to other natural fiber materials. Its moisture-wicking and stain-resistant nature, coupled with its silky-satin feel, also make microfiber sheets an excellent choice for sleepers who wish for quality, low-maintenance bedding.

Sweeten Your Sleep with Casper Sheets

Whatever your choice for material, be it a cotton sheet or microfiber sheet, know that you can’t go wrong if it’s made with quality. At Casper, we are intentional about the materials we use and the impact they will have on your sleep. Casper’s 100% organic cotton bed sheets envelop your bed in soft, crisp fabric for a comfortable, cool, and restful night’s sleep.

Browse our different types of bed sheets today and be one step closer to a cozy night’s sleep.

Visit our blog today for more fabric comparisons like Linen vs Cotton sheets and Percale vs Sateen sheets.

What is Microfibre Fabric: Properties, How its Made and Where

South Street Loft Microfiber Vivid Garden 4-piece Printed Sheet Set – Blue – Queen

What is microfibre fabric?

Microfibre is a synthetic fabric consisting of ultra-fine fibres. These fibres generally have diameters measuring less than 10 micrometers and have denier weights under 0.7 D. Comparatively, a single strand of silk is around 1 D, making microfibre one of the world’s finest forms of textile fibre.

Popularized by its use in cleaning products, microfibre has unparalleled softness, which has led to the rise of microfibre apparel and accessories. Microfibre is also highly durable, and it is both reasonably absorbent and water-repellant. Due to its impressive electrostatic qualities, microfibre also excels as a filtration mechanism, leading to a recent surge of interest in using this fabric as a protective face mask material.

Over the years, textile manufacturers have developed quite a few different types of microfibre fabrics, and new applications for this fabric within various industries continue to emerge. Despite its impressive beneficial properties, microfibre has a distinctly negative impact on the environment.

History of microfibre fabric

Textile manufacturers have experimented with extremely low-denier fabric fibres since the early 1950s. While early attempts to produce ultra-thin fibres were largely successful, it was difficult to control the length of the fibres produced, significantly limiting the potential applications of this new textile technology.

The first major breakthrough in mass-scale microfibre production occurred when textile manufacturers moved away from the melt-spinning process, which remains one of the primary production methods for other synthetic textiles, and began using bicomponent polymers that featured multiple types of textile plastics. These polymers proved to be much stronger than plastics consisting of single components, reducing the breakage that had previously occurred when extruding extremely thin textile fibres.

In the 1960s, the famed Japanese textile company Toray started mass-producing microfibre fabric for the first time. Dr. Miyoshi Okamoto proved to be the primary architect of the microfibre revolution, and with the assistance of Dr. Toyohiko Hikota, Toray produced a variety of microfibre fabrics including ultrasuede, which was one of the first microfibres to attain widespread popularity.

Aside from the notable exception of ultrasuede, however, use of microfibre fabrics remained highly limited in scope until the 1990s when Swedish textile manufacturers began producing a wide variety of other microfibre materials. Practically overnight, microfibre became a popular apparel material throughout Europe, and additional applications of microfibre in the arenas of cleaning and industry were also established. Therefore, while Toray is credited with the development of the first commercially successful microfibre fabrics, it’s likely that this material would not have become popular without the subsequent European microfibre revolution.

South Street Loft Paris Lace 4-piece Microfiber Sheet Set – Soft Grey – King

Microfibre fabric today

Microfibre continued to gain popularity in Asia and Europe throughout the 1990s, and by the early 2000s, this fabric had also become popular in North America and throughout the rest of the world. Due to the unique cleaning properties of microfibre, this fabric became a staple textile for washcloths, kitchen towels, mopheads, and a variety of other cleaning materials. While microfibre clothing never became as popular in the rest of the world as it was during the 1990s in Europe, microfibre apparel and accessories remain reasonably popular within certain niche applications.

Recently, the popularity of microfibre has endured a significant hit due to the ongoing controversy surrounding microfibre pollution. Despite the somewhat misleading nomenclature, microfibre fabric is not the greatest contributor to microfibre pollution, and common fabrics such as polyester and rayon actually contribute to this ecological disaster far more than microfibre fabric. Partially due to its name and also due to the fact that microfibre does, indeed, contribute to microfibre pollution, consumer sentiment toward this useful and inexpensive fabric has worsened.

Buy high-quality, low-priced microfibre fabric here . If you are UK based, you can buy it here .

How is microfibre fabric made?

Most microfibre fabrics consist of a combination of polyester and polyamide (nylon). Textile manufacturers produce these two fibres separately and then fuse them together using heat.

Structure of microfibres

Due to its relatively high tensile strength, it’s possible to form polyester into a wide variety of shapes. The cores of most microfibres are polyester, and these polyester cores are commonly star-shaped or asterisk-shaped.

Textile manufacturers then fit polyamide into the gaps between the “points” of these polyester fibres. Polyamide is considerably less dense than polyester, and it has less tensile strength. Therefore, it’s difficult to make polyamide into complex shapes, but this textile serves as an ideal filler substance.

Together, polyester creates the structure of microfibres, and polyamide provides the bulk. When used for cleaning cloths, polyester is responsible for the scrubbing action while polyamide provides absorbency and improves the thickness of the cloth.

Soft Pink Bow and Flowers Polyester Microfiber Fabric for bedding by the yard, half yard, and quarte

The microfibre production process

Since microfibres can be as small as 0.2 deniers in diameter, textile manufacturers cannot extrude the polyester fibres used in microfibre production through conventional spinnerets. Instead, they use long, metallic tubes, and the resulting polyester fibres are allowed to cool before they are melded with miniscule polyamide strips using heat.

At this point, it’s possible to dye microfibres or subject them to chemical treatments that improve heat resistance or provide other desirable qualities. Completed microfibres are then woven into long sheets of fabric and transported to facilities that manufacture end products.

Shop a wide variety of microfibre fabrics here for US and rest of world here and here if you are UK based.

How is microfibre fabric used?

Microfibre fabrics are used in a wide variety of different contexts. Here are a few examples of the ways that people around the world use this unique fabric:

Cleaning

Microfibre is uniquely suited for cleaning. The original designers of this fabric combined polyester with polyamide to provide a synergy of durability and absorbency.

Due to the unique design of its fibres, microfibre cloth can pick up more dirt and grime than other types of cloth. Scientific research suggests that microfibre may even be useful for removing dangerous microbes and viruses from surfaces.

Homewares

Since microfibre is highly absorbent and durable, fabric producers use this substance to make all sorts of different towels. From bath sheets to kitchen towels to washcloths, microfibre is an incredibly popular towel material.

While somewhat less common, microfibre is also used to make sheets and pillowcases as a result of its absorbency and unparalleled softness. Furniture manufacturers sometimes use microfibre as an upholstery material due to its combined absorbency and moisture impermeability. Microfibre is also a relatively common material for rugs and throw blankets.

Intelligent Design Microfiber All Season Wrinkle-Free Bed Sheet Set (Twin XL- Aqua), Blue, ID Intelligent Designs

Industry

Microfibre’s electrostatic properties make it an excellent filtration material. As a result, this substance is used as an industrial filtration fiber in a variety of different applications. Some construction contractors and builders also use microfibre as an insulation material due to its high fibre density.

Apparel and accessories

The primary attributes of microfibre that make this substance desirable for apparel and accessories are its softness, durability, and moisture-wicking properties. Most commonly used to make women’s skirts and jackets, microfibre is also desired for its resistance to stains. Certain types of microfibre also reasonably approximate the hand of leather textiles, making this fabric popular for belts, wallets, handbags, and other accessory items that would otherwise feature genuine or imitation leather.

Where is microfibre fabric produced?

China is the world’s epicenter of synthetic textile production. As a result, the majority of the world’s microfibre products originated in China with the United States and European Union also being significant microfibre producers.

How much does microfibre fabric cost?

Microfibre is one of the least expensive textiles. While it can be marginally more expensive than less complex forms of polyester or polyamide, it is far more reasonably priced than silk, cotton, or other natural fibres.

What different types of microfibre fabric are there?

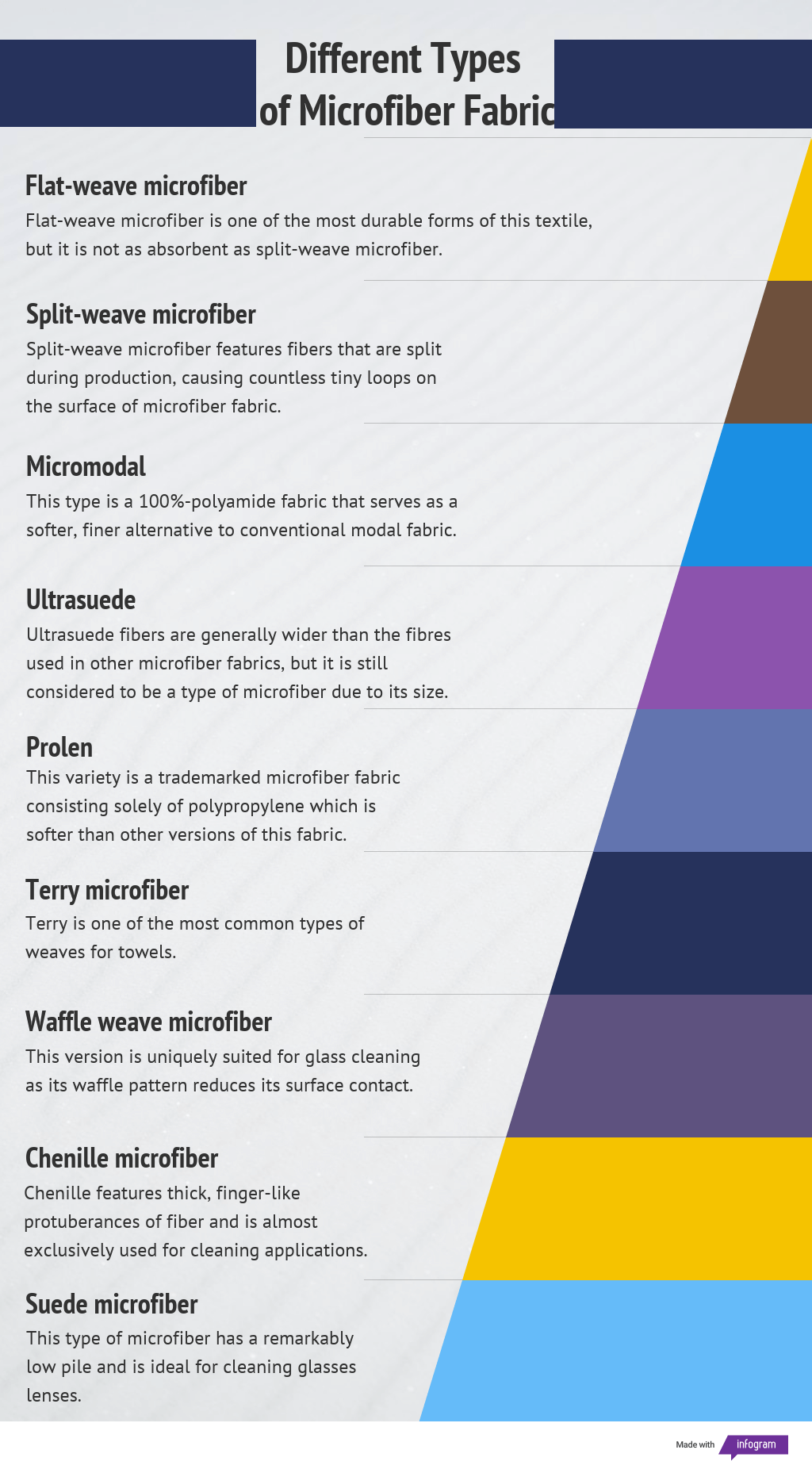

There are quite a few different types of microfibre. Here are a few of the most popular forms of this unique fabric:

1. Flat-weave microfibre

Flat-weave microfibre is one of the most durable forms of this textile, but it is not as absorbent as split-weave microfibre. Most microfibre garments and accessories feature flat-weave forms of this fabric.

2. Split-weave microfibre

Split-weave microfibre features fibres that are split during production, resulting in the formation of countless tiny loops on the surface of microfibre fabric. While flat-weave microfibre is soft and smooth, split-weave microfibre clings to your skin when you touch it.

3. Micromodal

Technically a type of microfibre due to the small diameter of its fibres, micromodal is a 100%-polyamide fabric that serves as a softer, finer alternative to conventional modal fabric. Compared to polyester-polyamide microfibre fabrics, micromodal is stretchier and less durable.

3 Pack Low Cut Microfiber Socks Black L

4. Ultrasuede

As one of the first microfibre products to be developed, ultrasuede is a competitor of genuine suede leather. Ultrasuede fibres are generally somewhat wider than the fibres used in other microfibre fabrics, but since they are under 1 denier in diameter, ultrasuede is considered to be a type of microfibre.

5. Prolen

Prolen is a trademarked microfibre fabric consisting solely of polypropylene. This textile can have either high or low elasticity, and it is somewhat softer than polyester-polyamide microfibre fabrics.

6. Terry microfibre

Terry is one of the most common types of weaves for towels, and many microfibre towels feature terry weaves. This type of microfibre is less commonly used in non-towel applications.

7. Waffle weave microfibre

Named for its raised, grid-like pattern, waffle weave microfibre is uniquely suited for glass cleaning. This type of microfibre’s waffle pattern reduces its surface contact, providing increased glide and reduced friction.

8. Chenille microfibre

Chenille microfibre features thick, finger-like protuberances of fibre held together by a thin base fabric. Commonly used to make sponges and car wash mitts, chenille microfibre is used almost exclusively for cleaning applications.

9. Suede microfibre

Designed to be soft like suede, this type of microfibre has a remarkably low pile. It is ideal for cleaning glasses lenses, and many types of apparel, accessories, and upholstery feature suede microfibre.

How does microfibre fabric impact the environment?

The environmental impact of microfibre fabric is considerably negative. Even though microfibre production only makes up a relatively small portion of overall synthetic textile production worldwide, this substance has a polluting effect during every stage of its use cycle.

Producing polyester and polyamide involves a variety of toxic, man-made chemicals that are either difficult or entirely impossible to dispose of properly. During use, microfibre fabric releases plastic microfibres into the hydrosphere, contaminating waterways and contributing to plastic pollution. Once its useful life has expired, microfibre fills up landfills or becomes a polluting plastic since neither polyester nor polyamide are biodegradable.

Microfibre fabric certifications available

Microfibre fabric consisting of recycled fibers may be eligible for Global Recycle Standard (GRS) certification. Additionally, the International Organization for Standardization (ISO) provides certifications for various grades and types of microfibre fabric.