How to build a DIY Murphy Bed

Cut a 2×4 to 75 inches and place it in the middle of the box stretching from the top to the bottom, centered at 28-1/4 inches. Screw through the 1×6 boards into the ends of the 2×4.

How to Build a DIY Murphy Bed

:max_bytes(150000):strip_icc()/d-12-2-8db06fa7c0fb4d4382b29b8222aa43d2.jpg)

Kamron Sanders is a home improvement expert and writer with over 15 years of hands-on construction, remodeling, woodworking, home repair, and landscaping experience. He has also written for HGTV. Kamron’s expertise ranges from troubleshooting saws and lawnmowers to painting kitchen cabinets.

- Working Time: 6 – 8 hrs

- Total Time: 1 – 2 days

- Yield: One Murphy bed with stylish cabinet doors

- Skill Level: Advanced

- Estimated Cost: $600 to $700

Building a DIY Murphy bed can help you reclaim your floor space while maintaining a comfortable, easy-to-set-up spot for overnight guests.

Murphy beds or wall beds are beds that fold away against the wall when not in use, often within an enclosed cabinet. This DIY Murphy bed can be built for under one thousand dollars which include the cost of a Murphy bed hardware kit. This DIY will have handy features like reading lights, electrical outlets, and USB ports.

Read ahead to learn how to build your own Murphy bed that looks great when not in use and won’t break the budget.

How Much Does a DIY Murphy Bed Cost

It’s much cheaper to build a Murphy bed than to buy one. Buying a Murphy bed can cost upwards of $3,000, with luxury options exceeding the $10,000 mark. Having a carpenter build a custom Murphy bed can easily cost just as much.

On the contrary, materials like plywood and solid wood for a Murphy bed will only cost a few hundred dollars. If you opt to use a Murphy bed hardware kit as we do in this tutorial, you can plan on spending another few hundred dollars.

Some DIYers opt to forgo the Murphy bed hardware kits when building a Murphy bed in order to save some money. The tradeoff is the ability to hide the legs and the assisted opening. If these attributes aren’t of great value to you, building a DIY Murphy bed without the hardware kit is simple.

The Cost of Wood for a Murphy Bed

On average, the wood needed to build a basic Murphy bed will cost less than $400. As with many DIY projects that use wood, you can make a DIY Murphy bed more or less expensive with the type of wood you choose.

This Murphy bed DIY utilizes a mixture of nominal pine lumber and plywood, as these are strong, solid options that won’t break the bank. If you’re looking for a more luxurious finish, you can swap the appearance boards for materials like oak and stain them rather than paint them.

Murphy Bed Kits and Hardware

Rather than designing this DIY Murphy bed tutorial around one specific hardware kit, we’ve made it adaptable to many. Generally, Murphy bed hardware kits will come with three things: legs, mattress straps, and springs or pistons for lifting and lowering the bed.

Some Murphy bed hardware kits may come with fewer or additional accessories, but you can typically count on these three items being included. These kits come from many different manufacturers and retailers in a variety of sizes, including twin, full, queen, and king. You can expect to pay a little more as you go up in bed size.

In addition to hardware kits, we’ve designed this Murphy bed tutorial to include integrated outlets with reading lights and USB ports to take advantage of covered outlets.

Before You Begin

The steps below outline how to build a DIY Murphy bed to accommodate a full mattress (54 inches by 74 inches) and any materials and cuts mentioned follow suit. If using another mattress size, remember to adjust everything accordingly.

Additionally, this DIY Murphy bed will utilize a Murphy bed hardware kit, but the tutorial is meant to be adjusted to your specific hardware kit. When in doubt, reference your Murphy bed hardware kit’s manufacturer’s instructions and employ any provided templates for leg hardware and springs or pistons.

Safety Considerations

Securing your DIY Murphy bed wall cabinet to the wall itself isn’t optional. Not only will failure to do so pose a significant safety risk, but it will also compromise the function of the Murphy bed, as it relies on the strength of the wall during opening and closing.

What You’ll Need

Equipment / Tools

- Measuring tape

- Pencil

- Stud finder

- Level or laser level

- Miter saw

- Jigsaw

- Brad nailer with nails

- Drill

- Drill bits

- Iron

- Painting supplies

- Orbital sander with sandpaper

- Caulk gun

- Oscillating multitool (optional)

- Pry bar

- Ladder

Materials

- Murphy bed hardware kit

- Combination outlet extension and reading light

- 2 1×8 x 8′ pine boards

- 3 2×2 x8′ pine boards

- 1 2×4 x 8′ pine board

- 2 2×4 x 10′ pine boards

- 2 1×6 x 10′ pine boards

- 4 1×4 x 10′ pine boards

- 1 3/4″ x 4′ x 8′ sheet sanded plywood

- 2 1/4″ x 4′ x 8′ sheet sanded plywood

- 1 1/2″ x 4′ x 8′ sheet sanded plywood

- 3/4″ iron-on edge banding

- Wood glue

- 12 1/4″ x 3-1/2″ lag bolts

- 12 1/4″ fender washers

- 2″ wood screws

- 2 Cabinet pulls

- Painter’s caulk

- Painting supplies

- Bare wood primer

- Interior paint

Instructions

How to Build a DIY Murphy Bed

Build Mattress Base Sides

Cut two 2×2 boards to 75 inches and two 1×8 boards to 75 inches. Glue and screw a 2×2 along the bottom edge of a 1×8, pre-drilling and placing 2-inch screws every 6 inches. Repeat with the second 1×8 and 2×2.

Radius the Mattress Base Sides (optional)

Some Murphy bed hardware kits require the tops of the mattress base to have a radius to accommodate the hardware and the movement of the bed when opening and closing it. If yours requires this, use the provided template and a jigsaw to cut the radius from each top corner of the sides.

Attach Top and Bottom

Place the assembled sides on your work surface with the 2x2s at the bottom. Cut two 1×6 boards to 56-1/2 inches and place them at each end of the sides. Glue the joints and screw through the 1x6s into the ends of the 1x8s and 2x2s to form a box.

Tip

To make hiding screw heads easier, countersink the screws by partially drilling into the wood with a drill bit just larger than the screw’s head, or using a special countersink drill bit.

Attach Middle Support

Cut a 2×4 to 75 inches and place it in the middle of the box stretching from the top to the bottom, centered at 28-1/4 inches. Screw through the 1×6 boards into the ends of the 2×4.

Attach Mattress Supports

Cut eight 1×4 boards to 55 inches and place them equally spaced across the inside of the mattress box. Glue and screw them to the 2x2s and the 2×4.

Attach Mattress Straps

Attach the mattress straps if it’s included in your hardware kit according to the manufacturer’s instructions.

Mount Leg Hardware and Legs

On the bottom end of the base, mount the leg hardware included in your hardware kit according to the manufacturer’s instructions. Use any provided templates or dimensions for positioning. Pay close attention to whether the legs are to be placed on the outside or inside of the base’s sides. Once the hardware is in place, attach the legs.

Mount Pivot Mechanism

At the top end of the base, mount the hardware for the pivot mechanism (spring or piston) using any templates or dimensions provided by the manufacturer for placement.

Determine Wall Cabinet’s Dimensions

- The pivot mechanism’s distance from the floor and the required gap are between the outside of the mattress box and the inside of the wall cabinet. The distance from the floor will determine the height of your sides, as the cabinet’s total height will have to accommodate the length of the bed box when closed.

- The gap will determine the width of the top and bottom boards to ensure there is room for the hardware.

Second, the thickness of your mattress will determine the required depth of your cabinet, as the cabinet will need to be deep enough to fit the mattress when closed.

Use all of these dimensions to determine the size of your wall cabinet.

For demonstration purposes, assume the required interior height of the cabinet is 80 inches, the interior width is 60 inches, and the interior depth is 13 inches. Adjust these dimensions as needed.

Cut Wood for Wall Cabinet

Use a table saw or a circular saw with a straight edge to cut the 3/4-inch plywood into two pieces measuring 15 inches by 80 inches (sides). Cut another piece measuring 15 inches by 61-1/2 inches (top). Cut four 2x4s to 60 inches.

Attach Edge Banding

Attach iron-on edge banding to one side of each plywood piece following the manufacturer’s instructions for application and trimming. On the top piece, edge band the sides as well.

Mark the Wall

Mark the wall for your desired cabinet location. Mark each stud’s location as well to make it easier to find at a glance.

Attach the Wall Supports

Pre-drill and attach a 2×4 to the wall with the top edge positioned at 80 inches, using 1/4-inch by 3-1/2-inch lag bolts with washers. Attach a second 2×4 on the wall against the floor. If necessary, cut and remove the baseboard using an oscillating multitool and a flat pry bar. Attach a third 2×4 with its top edge at 33-1/2 inches.

Mount Cabinet Sides

Stand the cabinet sides up with the edge banding facing outward and screw through the cabinets into the ends of each 2×4. Place the fourth 2×4 on the floor against the outside edge of the cabinet and screw through the cabinet into the 2×4.

Attach Cabinet Top

Place the top cabinet piece on top of the side pieces with the edge piece facing outward. Screw through the top piece into the tops of the side piece using 2-inch wood screws.

Cut and Attach Vertical Nailers

Cut 2×2 boards into two pieces measuring 42.75 inches and two pieces measuring 18.25 inches. Place the longer 2x2s between the top 2x4s against the cabinet sides, then screw them into the cabinet sides using 2-inch wood screws. Place the remaining boards beneath the middle 2×4 and against the cabinet sides.

Cut Back Pieces

Cut 1/4-inch plywood into one piece measuring 60 inches by 48 inches. Cut a second piece measuring 60 inches by 20 inches.

Mount Recessed Outlet and Reading Light (optional)

If you’re opting to mount the recessed outlet and reading light to take advantage of a covered outlet, cut the hole for the outlet at least 2 inches below the top edge of the 20-inch tall piece of plywood. Make sure to follow the manufacturer’s instructions for measuring and cutting the hole. If you want a reading light and outlet on each side, position them evenly toward each vertical edge of the 1/4-inch plywood piece.

Mount Back Pieces

Apply a bead of glue to each 2×4 and 2×2, then slide the plywood into place between the cabinet sides and secure with brad nails. Start with the top piece, then place the bottom piece. The bottom piece is left intentionally unfastened across its bottom edge to allow access to the covered outlet.

Mount Pivot Mechanism Hardware

Using the manufacturer’s instructions and any provided templates, mount the pivot mechanism hardware on the cabinet sides.

Mount Bed Box in Wall Cabinet

Use the manufacturer’s instructions to attach the pivot mechanism and mount the bed box within the wall cabinet. Lift and lower the bed to test its functionality and make any adjustments before moving forward.

Cut and Attach Outside Bed Box Cover

Cut 1/2-inch plywood into two pieces measuring 30 inches by 76-1/2 inches. With the bed in the closed position, glue and brad nail the pieces to the front of the bed box.

Cut and Attach Faux Door Trim

Rip 1/4-inch plywood into 3-inch-wide strips. Cut four strips to a length of 30 inches and four strips to a length of 70-1/2 inches. Glue and brad nail the strips around the perimeter of the 1/2-inch plywood to create a faux door.

Attach Door Pulls

To sell the look of the faux cabinet door, attach door pulls by drilling holes and using their provided hardware. You’ll likely have to lower the bed to secure the nuts on the back side. These also will make it easier to lower the bed by providing a firm place to grab.

Attach Top and Bottom Trim to Cabinet

Cut and attach a piece of 1×6 top and bottom trim to cover the exposed interior of the cabinet when the bed is in the closed position. The width of these trim boards will be dependent on the position of your pivot mechanism on the bed and cabinet and you may have to choose a narrower board to accommodate your kit.

Tip

To further enhance the “built-in” look of your DIY Murphy bed, consider adding additional moldings like cove and baseboards where it meets the wall and floors.

Prime, Caulk, and Paint Everything

Prime all bare wood using a bare wood primer, applying and reapplying according to the manufacturer’s instructions. Once dry, caulk every joint and seam, and fill every nail and screw hole. If necessary, drive the nails further into the wood using a nail set. Once the caulk dries, paint all surfaces with your desired paint color.

More DIY Murphy Bed Projects

There’s no one way to build a DIY Murphy bed. Here are other Murphy bed projects that you can try out:

- Modern Farmhouse Murphy Bed: This Murphy bed office combo by Katie at the Addicted 2 DIY includes bookcases and a desk. The frosting on the cake is the bed cabinet. When closed, it resembles a storage wall so those not in the know would never guess it conceals a mattress.

- IKEA Murphy Bed Hack: Paul from Renovations and Old Houses built his DIY Murphy bed using pieces from IKEA’s PAX series. The project incorporates a floor-mounted bed frame with a spring mechanism. When folded up, it looks like a regular cabinet.

- Basic DIY Murphy Bed Using Rockler Hardware Kit: This Murphy bed project by David Picciuto at “Make Something TV” shows how to make a simple Murphy bed using side-mount deluxe Murphy bed hardware from Rockler. Each kit includes instructions, but if you find them confusing, Picciuto includes a video that gives an overview of the steps.

What is the difference between a Murphy bed and a wall bed?

While the terms “Murphy bed” and “wall bed” have become synonymous, in the past, a Murphy bed implied using a spring mechanism while wall beds used pistons.

Some alternatives include trundle beds, fold-out sofa beds, futons, and air mattresses.

You can turn some platform beds into a Murphy bed by adding hardware and building a wall cabinet, but a better and safer route would be to make a Murphy bed.

Measurements must be exact when constructing a Murphy bed. But a prefabricated Murphy bed kit can take some guesswork out of the process.

Not all Murphy beds are attached to a wall. There are also floor-mounted options available.

You typically can leave sheets and possibly even quilts and thin duvets on a Murphy bed when it’s in the raised position. But this can vary based on the bed model.

How to build a DIY Murphy Bed

For today’s project, we’ll cover the process of how to build a DIY Murphy bed. A Murphy bed will make your home or space more efficient and will free up the room to use for other purposes. That guest bedroom can now be used as an office, exercise area, or playroom for the kids. The investment in time and money for this DIY Murphy bed will be well worth it!

DIY Murphy Bed Options

100% DIY Hardware ( cheapest method )

There are a number of ways to build a DIY Murphy bed. I chose to use a DIY Murphy bed kit for all of the hardware to save time and to make sure the bed works perfectly. I also wanted our DIY Murphy bed to look professional and be easy to raise and lower. If you are willing to take the time and don’t care about the gas springs or pre-made hardware, then I’d recommend checking out DIY Tyler’s Murphy bed build. He’s a great guy and has a lot of really cool projects. Here is a link to his Youtube video.

DIY Murphy bed with hardware kit ( my choice )

For those who want the professional DIY Murphy bed kit, you’ll invest around $300-500 depending on where and who you purchase the DIY Murphy bed kit from. I did a lot of research and ended up purchasing a gas spring kit on Amazon made by CreateABed for $299. I’ve been very happy with it and certainly would definitely recommend it. The DIY Murphy bed kit does come with plans for any size bed. I used their DIY Murphy bed plans for this build and customized the final product by adding trim on the front and sides.

Cut plywood and boards to size

Use a table saw or circular saw to cut the plywood down to size. Having an extra person to help with this process will make things much easier. A table saw is my tool of choice, but you can use a circular saw with a guide if you do not own one.

A circular saw works great for cutting the boards down in length. I use a 12 inch sliding compound miter saw from Dewalt.

Build the frame for the mattress

The mattress frame is built out of solid 1×2 boards. I used pine. A 1×2 board is actually 3/4 inches thick by 1 1/2 inch wide. Cut the boards according to the plans you will get with Create-a-bed. Pre-drill all holes. Use 1 1/2 inch screws and wood glue to assemble each of the 5 struts. Then use 2 inch screws to attach the side frame to each strut.

Build bed rails

The bed rails are made out of plywood. CreateaBed ( the manufacturer ) recommends using plywood because of its strength. Templates are provided to help with hardware mounting locations. Apply edge banding to all plywood with exposed edges that will be seen. This will give the wood a nice finished look and the appearance of a solid piece of wood.

Attach rails, headboard, and footboard

Attach the side rails, headboard, and footboard to your Murphy bed mattress frame. Pre-drill all holes. The head and footboard are connected to the side rails using 2 inch long screws.

Lay out the front panels

The front face of the DIY Murphy bed cabinet is made of two sheets of plywood cut to size. Apply edge banding to the three outer sides of each piece of plywood. You do not need to apply banding to the sides that touch each other in the center. On the outer left and right panel, you’ll want to measure in 1/4 inch and draw a line.

Center the DIY Murphy bed frame so there is a 1/4 inch overlap on each side. The footboard should be flush with the edge and the headboard will also have a little overlap. Use a pencil to trace around each strut. This will provide a template to show where to add glue. Remove the frame from the plywood, add glue, and then attach the bed frame to the panels. See the video for more details.

Attach the bed frame to the face panels using 1 1/4 inch #8 screws. Make sure to pre-drill before inserting the screw. Take your time lining up the panels to ensure they are square.

Add hardware to vertical cabinet sides

Add the hardware to the insides of each vertical cabinet piece. Add edge banding to the front side of each panel.

Build the header

The header will connect the two vertical cabinet pieces. You’ll also use the header as a part to screw threw to connect the unit to the wall in a later step.

Remove hardware, sand, and stain/paint

Once everything is built you’ll want to remove the hardware so the wood can easily be painted or stained. Then sand the wood with 220 grit sandpaper, paying specific attention to rough areas and anything that needs to be smooth out. Either paint or stain the project.

If you choose to stain the wood, I’d recommend using a brush on polyurethane to seal the project. I use a spray polyurethane for my project to speed up the process, but it doesn’t do as good of job for a large project such as this. Give the stain or finish a few days to dry and air out before taking it into your home.

Remove baseboard trim

Remove the baseboard trim so your new Murphy bed will have a tight fit against the wall. Another option is to contour cut the back of the vertical so it fits around your existing trim. Either option will work. I am slowly upgrading and replacing all the trim in my home, so I removed the old 1×4 existing trim and put in some new 1×6 trim.

Move Murphy bed into the home

Carry the cabinet vertical, header, and other hardware to the room it is being installed in. Next, move the bed frame. The bed frame is heavy and I’d recommend finding someone to help you. Put a large blanket or towels under the bed frame while moving it if you plan to slide it along the ground.

Attach verticals to bed frame

Add the spacer around the peg hardware and then put the peg through the bed frame hole. Place the metal clip at the end to secure it in place.

Connect the header

With a helper, rotate the two vertical boards up. Next, lift the header between the vertical boards. Clamp in place and attach. Attach from the inside so you will not see the screws.

Install gas springs and stoppers

Push the bed frame up and slightly past the front of the cabinet unit. Attach the gas springs. This can be a bit tricky and will definitely require another person to help hold the bed while the other person is installing the stoppers and gas springs.

Once the springs are in, you can add the stoppers. Because the gas springs are now installed, I used a scrap piece of wood to hold the panel out while we installed each stopper. The yellow arrow points toward the scrap wood that is helping prop the door so we have room to add the stopper.

Attach to the wall

Use a stud finder to find the studs in your wall. Next, push the cabinet unit against the wall. Attach the top header to the wall at each stud location using 3 inch wood screws. After attaching the top, I put a a couple screws through the lower portion of the headboard near where the mattress will eventually go.

Add trim

In the manufacturer’s directions, they will add the handles and 1/4 inch plywood earlier in the process. However, I was unsure how I wanted to do the trim and so I added the handles later in the build. I made a temporary pull so I could still open the bed without the hardware installed. I did 1×6 trim around the top and bottom of the unit. The corners are mitered.

Note the baseboard trim is only attached at each vertical board with 3 finish nails. Do not connect it to the face panels because it would then rotate with the entire bed and pull away from the unit.

The upper 1×6 board is attached to the header. It is placed flush with the front bottom of the header so their is a small gap between the trim and the door portion. This does not connect to any moving parts and can be nailed anywhere to the header.

I then added the same trim to the sides of the unit.

Trim was then added to the front face panels. The first piece goes flush with the left side of the face panel and the top of the face panel. There should still be a small gap between the top of this board and the upper 1×6 trim.

Attach both vertical pieces and then the top horizontal piece. Make sure there is still a small gap between this piece and the top 1×6 molding.

Add the lower trim. You’ll notice there is about an inch of space between this trim and the baseboard. This is necessary so the door can pivot.

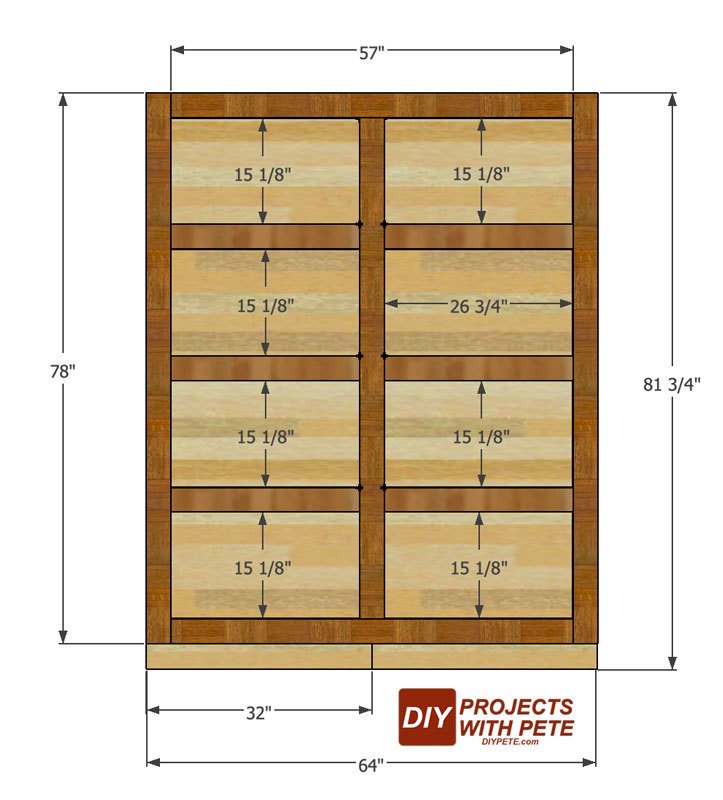

Here is a diagram showing my front panel trim boards. I used 1×4 boards for this part of the build. The baseboard and top molding are made out of 1×6 boards.

Add the center board and then horizontal ones. I used 3 horizontal boards on each side, but feel free to modify or do the trim however you’d like!

Add handles

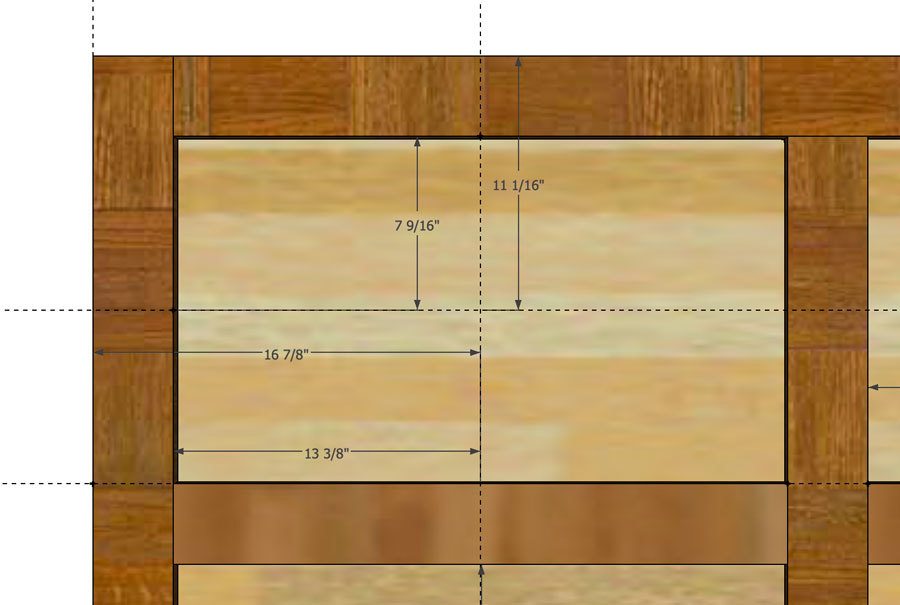

The handles should be around 5 to 6 feet or so off the ground for optimal leverage. Most folks put the handles and face trim on earlier, but I wasn’t exactly sure how I wanted the trim to look, so I added it all once in the bedroom. I wanted to center the handles in the two top panels.

The 10 inch bar pulls are pretty cheap on Amazon. Make sure the handles are added before the 1/4 inch backing is attached.

The diagram below shows the center of the panel where the cabinet handle is placed. Use these measurements to help with placement if needed.

Attach 1/4 inch plywood

Use short screws ( 1 inch long or whatever you have that is convenient ) to attach the plywood to the struts and rails of the inner frame. As I mentioned, you could add the handles and plywood earlier if you have the trim layout figured out earlier, or if you go without trim. Use weights or something heavy to hold down the bed during this step.

Connect mattress straps

Measure about 16 inches in from each corner. Attach the elastic strap using short screws.

Install mattress

Slide the mattress into place and put the elastic straps over each corner. These will hold the mattress in place when it is lifted. You’ll need to use a mattress that is 12 inches in thickness or less. I measured all the mattresses in my home and they were all between 10-12 inches in thickness.

Enjoy!

Put the bedding on and enjoy the new bed! People love seeing Murphy beds and it is fun to show visitors how it works. I added temporary night stands until I build some new and lower nightstands that match.

Please share your Murphy bed project in the comments and let me know if you have any questions!