Wood Retaining Walls

If using a retaining wall for terracing a slope so you have more landscaping options, map out your landscaping plans to determine where it will function best. The best spot is the one that needs it the most; if a slope is eroding or has become a dead area of unusable land, that’s a good location.

How to Build a Solid Wood Retaining Wall

:max_bytes(150000):strip_icc()/headshots_FINAL_lee-wallender-739d21a7b6ed4aa1b895c684e193494c.png)

Lee has over two decades of hands-on experience remodeling, fixing, and improving homes, and has been providing home improvement advice for over 13 years.

:max_bytes(150000):strip_icc()/headshots_FINAL_deane-biermeier-842c201b7d0244dbb856926dd97ed720.png)

Deane Biermeier is an expert contractor with nearly 30 years of experience in all types of home repair, maintenance, and remodeling. He is a certified lead carpenter and also holds a certification from the EPA. Deane is a member of The Spruce’s Home Improvement Review Board.

:max_bytes(150000):strip_icc()/_DSC3035-89e8764848db4aa6901d9451b9b15923.jpeg)

Sarah Scott is a fact-checker and researcher who has worked in the custom home building industry in sales, marketing, and design.

:max_bytes(150000):strip_icc()/WoodRetainingWall-GettyImages-692776409-74e1cdf3036347f1a5cdb6942bd1272a.jpg)

- Working Time: 4 – 6 hrs

- Total Time: 1 – 2 days

- Skill Level: Intermediate

- Estimated Cost: $200-$400

Building a wood retaining wall helps to reshape slopes on your property to create level areas for driveways, gardens, paver patios, children’s play areas, and decks. Retaining walls also keep soil and vegetation away from established structures. A retaining wall using timber vs. concrete blocks is often preferable to keep the landscape looking more natural.

What Is a Retaining Wall?

A “retaining wall” holds back (or “retains”) the soil behind it and is often used for erosion control, terracing, and designing outdoor spaces.

Since large, thick pieces of timber are heavy and unwieldy, you can go an easier route and build a wood retaining wall using lighter-weight dimensional pressure-treated lumber as long as the height of the retained soil stays relatively low.

Read on for step-by-step instructions to build a straight, 16-foot-long wood retaining wall that is 24 inches high. This construction method is suitable only for low walls that reach a maximum of 30 inches. Taller walls require a different type of structure. For durability, use only pressure-treated lumber rated for ground contact.

What to Consider Before Building a Wood Retaining Wall

The wall and the soil behind it must remain low because heights over 30 inches will result in too much pressure against the back of the wall, and the wall may eventually bend over and fail.

A big advantage of building a low wood retaining wall is you do not need unwieldy tie-backs dug back into the slope, like many of the four-by-four timber retaining walls. Nor do you need to rely on sheer weight, plus a slight tilt, to hold back the slope, like masonry walls. Instead, post holes are dug for fence posts. Pressure-treated boards are then nailed across the backs of the posts, much like boards on a fence.

Constructing a solid wood retaining wall using heavy timber or long, unwieldy wooden boards can be cumbersome. Consider recruiting a helper when hauling the items to the work area and nailing in the boards. A second person is also handy to assist in leveling and excavating the site.

Remove all rocks, refuse, and plants to prepare the work area. Uproot all the plants if they are in the way of your wall. Rake the area smooth, making it level.

When to Build a Solid Wood Retaining Wall

The best time to build any retaining wall is when the ground is dry. If possible, select a time that has not had much rain in the previous week and none is in the forecast for the next three days. In many regions, late spring or early summer after the early spring rain period works well.

Winter is one of the worst times to build a retaining wall since the ground is frozen in most parts of the country. However, if you live in a frost-free region, winter is a viable option if dry.

Choosing a Location

If using a retaining wall for terracing a slope so you have more landscaping options, map out your landscaping plans to determine where it will function best. The best spot is the one that needs it the most; if a slope is eroding or has become a dead area of unusable land, that’s a good location.

In spots where the soil has begun eroding, the topsoil becomes thinner. Signs of soil erosion include exposed roots, spots of no plant growth, or compacted, hard soil spots.

Avoid choosing a location where you notice puddling, muddy soil, or water oozing up from the ground since these conditions will rot wood much quicker.

Codes and Regulations

Check with your local permitting office for information about recommended retaining wall dimensions.

What You’ll Need

Equipment / Tools

- Post hole auger or manual post hole digger

- Hammer

- Shovel

- Power miter saw or circular saw

- Bubble level

- Laser level

- Measuring tape

Materials

- 2 2 x 6 pressure-treated lumber boards, each 8 feet long

- 6 2 x 8 pressure-treated lumber boards, each 8 feet long

- 8 bags of 50-pound fast-setting concrete mix

- 8 0.8-cubic-foot bags of 7/8-inch drainage rock

- 2 wood stakes

- Scrap 2 x 4s

- Ordinary twine or yellow braided nylon mason line

- Box of 16d hot-dipped galvanized nails

- Wood preservative

Instructions

Plan Out the Retaining Wall

Stake out the area where you plan to build the wall. Pound a stake at one end, then drive another 186.5 inches away if you plan to extend the wall longer than 16 feet. Run the line from one stake to the next, pulling it tight.

Tip

Instead of making the distance 192 inches (16 feet), you’ll make it 186.5 inches to account for the width of the two end posts. If the wall is going to be longer than 16 feet, account for each end post being 5 1/2 inches wide.

Cut Into the Slope

With your shovel, dig about 2 feet back into the slope. You are only digging sideways, not down. You must dig far enough to give yourself enough room to work on the retaining wall. At the same time, the more soil you remove, the more you need to replace it with gravel backfill.

Prepare the Retaining Wall Area

With your shovel, follow the line and dig out a groove about 5 inches deep where the retaining wall will rest. Make sure that this groove is level from end to end by laying down one of the boards with the bubble level on top. The flat-bladed shovel or spade is the ideal width for scraping down areas of the groove or replacing soil in other areas.

Mark Other Post Locations

Pound six more stakes between the two end stakes. The stakes should be equally spaced apart from each other or roughly 2 feet apart on-center, each following the twine. You should now have eight stakes in a perfect line, each 2 feet away from its neighboring stake. Each stake represents the center position of a post hole.

Dig Post Holes

With wood retaining walls, the rule of thumb is that the height of the soil you hold back should roughly equal the depth of the post holes. So, you will be digging down 24 inches to account for the depth of the post, plus another 4 inches for a bed of landscape gravel. The hole for the 4-by-4 posts should be about 12 inches in diameter. Remove one stake at a time, then dig a hole with a post hole auger or manual digger (clamshell digger) at each staking point. With your tape measure, ensure each hole is 28 inches deep.

Add Gravel to Post Holes

Pour 4 inches of gravel into the bottom of each post hole. Be careful not to let soil drop into the holes. You should be able to spread one bag of gravel for every two holes (or four bags of gravel between the eight holes).

Set Posts in Holes

Cut each of the 2-by-6 posts in half so that you have eight posts, each post 4 feet long. Daub the cut ends of the lumber with wood preservative. Place the posts in each hole. Working one post at a time, use the laser level to ensure the post is aligned perfectly plumb. Use scrap lumber for stakes to hold it in place.

Tip

While the faces and factory-cut ends of pressure-treated wood are protected, the ends of site-cut wood are not protected. A copper-based wood preservative is commonly used on cut ends of pressure-treated lumber. The copper solution effectively replaces the preservative injected into the wood mill’s wood.

Pour Concrete

Pour one bag of dry quick-set concrete into the hole, followed by the recommended amount of water per the product instructions. Leave the scrap lumber stakes in place until the concrete is set before moving on to the next post. Fast-setting concrete sets in about 30 to 40 minutes. Even so, it’s usually best to let the concrete fully harden for at least four hours.

Add Gravel Under Wall Location

Add 2 inches of gravel to the groove where the wall will rest. The gravel will help water drain away and prevent premature rotting of the wood. Water can rapidly wick upward through the wood and damage the entire retaining wall.

Install Retaining Wall Boards

Install three rows of 2-by-8 boards horizontally behind the posts, starting at the top and working down. The top row of boards should be flush with the tops of the posts. Nail the 2-by-8s to each post with two 16d nails, nailing through the slope side of the boards and into the posts. Install a final row of boards along the bottom, using 2-by-6 boards. The bottom edge of this row will be about 2 inches below ground level.

Warning

Install the boards on the slope side of the posts. If you install the boards on the opposite side of the posts, wall strength and stability are significantly compromised. When installed on the slope side, the boards can press against the posts as it gets pressure from the slope.

Back-Fill Slope Side of Wall

Pour the remaining bags of landscape gravel along the bottom of the retaining wall on the slope side, distributing it evenly. The gravel promotes drainage along the bottom of the wall. Backfill the rest of the cavity with soil. It’s vital to backfill with gravel and not with soil or even a combination of soil and gravel. If soil is used as a backfill, it will become water-logged and excessively heavy, potentially collapsing the retaining wall.

Tips for Building a Solid Wood Retaining Wall

Wood naturally decomposes over time. You must get pressure-treated wood that resists rotting, such as wood rated for ground contact. However, these wood types are more expensive. It’s worth the expense to extend the life of your wall. The average life of a wood retaining wall is about 10 years, although high-quality wood and double-treating it can help you keep your wall in good shape for about 20 years.

Wood preservatives, insect repellents like creosote to deter insect activity, and weather sealants are effective wood treatment options. Wood stain is another way to go; however, that will need reapplication every year or two.

If opting against using pressure-treated timber, another alternative is creosote-treated railroad ties, which you can usually source at big box home improvement retailers or lumber yards. Railroad tie lumber is usually a less expensive option.

To keep soil in place behind your retaining wall, consider using plantings. Plant roots help keep the soil in place, reducing erosion. However, if the plants die in winter, replace them in the spring. Voids left behind by dead foliage can loosen the soil.

When to Call a Professional

Hire a professional to build a wood retaining wall taller than 30 inches. The project becomes more complex the taller it gets since adding height usually means more pressure and natural forces will be exerted on the wall.

Also, contact an expert if the area where you want to build the wall experiences drainage issues. Professionals have engineering skills to account for significant runoff issues and a strong understanding of those related engineering considerations.

The Spruce uses only high-quality sources, including peer-reviewed studies, to support the facts within our articles. Read our editorial process to learn more about how we fact-check and keep our content accurate, reliable, and trustworthy.

- When a Permit is Required. Fairfax County Government Land Development Services.

- Information for Building Code Officials: How do I make sure the treated wood on the jobsite meets code? American Wood Protection Association.

- Browder, John O. Fragile Lands of Latin America: Strategies for Sustainable Development. Taylor and Francis, 2019.

Wood Retaining Walls

Wood retaining walls are affordable and can be very attractive.

In the right setting, a timber retaining wall blends into a landscape more naturally than any other material. When stained to match a log or cedar clad home, it carries the house materials into the landscape for a more unified appearance. In the woodland garden, they are particularly beautiful, composed of the very trees that surround them.

Wood Retaining Walls Are Affordable and Easy

In most cases, it’s the simple construction and low costs that make timber retaining walls the most common choice for do-it-yourself home improvement. This kind of wall is also an affordable way your landscape contractor can control short slopes that may erode or prove unstable over time. In recent years the demand for raised bed food gardens has brought a lighter version of this retaining wall into many new landscape projects.

Wood Retaining Wall

Large timbers, usually 6 x 6, can be stacked and reinforced by steel rods inserted through holes drilled through to grade.

Preservatives and Soil Health

There is a concern for the chemicals in railroad ties leaching into the surrounding soil. This has reduced their frequency in raised bed food gardens. In fact, many organic gardeners are concerned about all wood preservatives including those of new pressure treated lumber leaching into the soil. For this reason, the preferred material for food garden applications is the foundation grade redwood or cedar, which is a more expensive, but healthier choice.

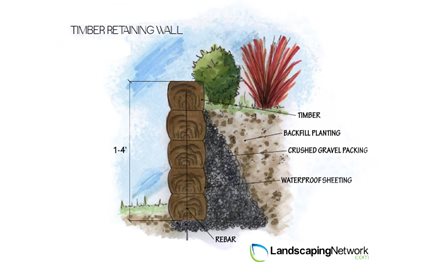

Building Timber Retaining Walls

A timber retaining wall is usually less than four feet tall. There are two basic construction methods, each one suited to different conditions. One utilizes upright stanchions anchored in a concrete footing, with horizontal wall planks, usually 2 x 6. This is often used for raised beds in the kitchen garden. The other method is composed exclusively of very large timbers, usually 6 x 6, stacked and reinforced by steel rods inserted through holes drilled through to grade. Extensions behind the wall known as deadmen extend back into the slope and provide additional reinforcement against bowing. Your contractor will select the best construction method for your landscape application.

A timber wall, if well built with proper materials, waterproofing and preservatives can last for about 20 years or more. The primary weakness is the wood itself, which is subject to rot due to extensive wood to earth contact. Because there is moisture in the earth which increases lateral earth pressure, the combination of weight and rot is what typically causes failure. This vulnerability shortens the lifespan of wood walls compared to block or concrete walls.

Preventing Moisture Problems

To maximize your timber wall longevity, the contractor must pay close attention to water, where it gathers and pools both on top and behind the wall. The accumulation of moisture speeds the decomposition of wood, so drainage structures are very important as is the overall grades both at the top and toe of the wall.

The best kind of lumber for these walls is Douglas fir pressure treated with preservatives to discourage rot. It will be green or brown in color and rated for earth-to-wood contact. For timber walls, large timbers for can be very expensive, which is why railroad ties are a common alternative. These recycled ties are more affordable than new lumber with increased weight and stability. Railroad ties are heavily treated with potentially toxic wood preservatives and creosote. The disadvantages are a chemical odor when superheated by summer sun.

In most cases a layer of waterproof sheeting is applied to the back side of the timber retaining wall to separate it from direct contact with fill. There is also gravel packing behind the wall, particularly at the bottom where water accumulates during rainy conditions. The gravel extends the length of the wall and may also contain perforated tubing to create a French drain that shunts water to one or both ends of the wall so it won’t accumulate. While some walls do feature weep holes at the bottom, this will shorten the life of the wall due to rot prone conditions caused by perpetual moisture entering the wood and spreading from these points.

Related Reading: